- Duplex Steel S31803 Plates Supplier in Qatar

- Corrosion Resistance of Duplex Steel S31803 Pipe Fittings: A Comprehensive Guide

- A Comprehensive Beginner's Guide to Duplex Steel Pipes

- Choosing the Right Duplex Steel Sheets and Plates for Your Project

- Duplex Steel Sheets and Plates: The Perfect Choice for Offshore Applications

- Duplex Steel S31803 Coils in marine environments: Performance and suitability

- Comparing duplex steel 2205 plates with other types of stainless steel alloys

- Duplex Steel 2205 Plates in the Construction Industry: Applications and Benefits

- Understanding Duplex Steel 2205 Sheets: Composition, Properties, and Applications

- Applications and Advantages of Duplex Steel 2205 Sheets in the Oil and Gas Industry

- Manufacturing Process of Duplex Steel S31803 Plates

- Welding and Fabrication of Duplex Steel S31803 Plates

- Advantages of Duplex Steel S31803 Plates over other types of steel

- Comparing duplex steel 2205 plates with other types of stainless steel alloys

Welding and Fabrication of Duplex Steel S31803 Plates

Welding and fabrication of Duplex Steel S31803 Plates require careful consideration due to the unique properties of this alloy. Here are some important points to keep in mind when welding and fabricating Duplex Steel S31803 Plates:

Pre-weld Preparation: Before welding, it is important to clean the surface of the plates thoroughly to remove any contaminants. It is also recommended to use a preheat treatment to avoid any thermal shock to the plates.

Welding Techniques: The preferred welding technique for Duplex Steel S31803 Plates is gas tungsten arc welding (GTAW) or gas metal arc welding (GMAW). Both of these techniques offer good control over the welding process and produce high-quality welds.

Welding Consumables: It is important to use the appropriate welding consumables for Duplex Steel S31803 Plates. The filler material should have a matching chemical composition and mechanical properties to the base metal.

Post-weld Treatment: After welding, it is recommended to perform a heat treatment process to reduce the risk of stress corrosion cracking. This process typically involves annealing, quenching, and tempering.

Fabrication Techniques: Duplex Steel S31803 Plates can be easily fabricated using conventional techniques such as cutting, bending, and machining. However, it is important to use tools that are designed for cutting and machining duplex stainless steel.

Design Considerations: When designing structures or components using Duplex Steel S31803 Plates, it is important to take into account the unique properties of this alloy. For example, the coefficient of thermal expansion is higher than that of austenitic stainless steel, which can lead to distortion during welding.

Overall, welding and fabrication of Duplex Steel S31803 Plates require careful attention to detail to ensure that the finished product meets the required specifications. With proper preparation, welding techniques, and post-weld treatment, Duplex Steel S31803 Plates can be successfully welded and fabricated to produce high-quality structures and components.

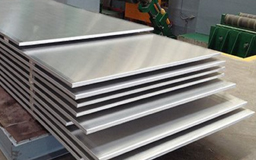

Duplex Steel Sheets & Plates Specification

| Material | Duplex Steel |

| Form | Plain Sheets, Plates, Coils, Foils, Shim Sheets, Rolls, Perforated Sheets, Chequered Plates |

| Thickness | 0.3mm To 200mm |

| Width |

200mm to 3000mm |

| Length | 500mm to 12000mm |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA, NO.1, NO.4, NO.8, Satin (Met with Plastic Coated), 8K, mirror, etc |

| Grade | ASTM / ASME SA 240 Duplex Steel 2205, UNS S32205, UNS S31803 |

Duplex Steel 2205 Plates, Duplex Steel Sheets, Duplex Sheet Coils, Duplex Steel Foils, Duplex Shim Sheet, Duplex Steel Rolls, Duplex Sheet Perforated Sheet, Duplex Steel Chequered Plates Supplier & Stockist in India

Duplex Steel 2205 Sheets, Plates, Coils - Application Industries

- Automobile Industries

- Boilers

- Chemical Fertilizers

- Desalination

- Decoratives

- Dairies and Food

- Energy Industries

- Food Industries

- Roofing Industries

- Switchgear Industries

- Heat Exchangers

- Instrumentation

- Metallurgical Industries

- Oil and Gas Industries

- Pharmaceuticals

- Power Plants

- Railings In Railway Stations

- Sugar Industries

- Space Application

- Pulp and Paper Mills

- Railway Coachings

- Ships

We Export To

Brazzaville, Port Elizabeth, Peru, Saudi Arabia, Benin, Cape Town, Democratic Republic of the Congo, Sudan, Dar es Salaam, Maiduguri, Houston, Douala, Luanda, Kano, Sri Lanka, Africa, Vietnam, Uganda, Italy, Ghana, Brazil, Durban, Subra al-Haymah, Maputo, Soweto, New York, Ethiopa, Iraq, Pretoria, Fez, Lagos, Giza, Kampala, Zaria, Bulawayo, Trinidad and Tobago, Conakry, Antananarivo, Iran, Cairo, Mexico, Hong Kong, New Zealand, Azerbaijan, Morocco, Chine, London, Algeria, Accra, Malaysia, Port Harcourt, Algiers, Casablanca, Jordan, Freetown, Abidjan, Kinshasa, Argentina, Angola, Thailand (Bangkok), Venezuela, Russia, Nigeria, Singapore, Cameroon, Mozambique, Egypt, Addis Ababa, Lebanon, Dubai, Harare, Qatar, Germany, UAE, Mbuji-Mayi, Kolwezi, Khartoum, Oman, Ouagadougou, Alexandria, Kazakhstan, Kaduna, Nairobi, Rabat, UK, United States, Ibadan, Tripoli, Indonesia, Turkey, Canada, South Africa, Lubumbashi, Abu Dhabi, Colombia, Bahrain, Bamako, Colombo, Kuwait, Tunisia, Dakar, Omdurman, Johannesburg, Australia, Cyprus, Yemen, Israel, Yaoundé, Mogadishu.We Supply To

Maputo, Port Harcourt, Freetown, Angola, Russia, Kampala, Baraut, Johannesburg, Venezuela, Fez, Sadar, Muktsar, Kano, Nagapattinam, Luanda, Addis Ababa, Jamalpur, Colombo, Harare, Bundi, Douala, Cyprus, Nairobi, Port Elizabeth, Puducherry, Kolwezi, Manipur, Democratic Republic of the Congo, Andhra Pradesh, Bhiwadi, Maharashtra, Udgir, Brazzaville, Kolkata, Zaria, Mizoram, Qatar, Suryapet, Durban, Omdurman, Mogadishu, Ouagadougou, Uganda, Casablanca, Alexandria, Buxar, Bamako, Delhi, Antananarivo, Yemen, Ambala, Benin, India, Hong Kong, Maiduguri, Kerala, Singapore, Jordan, Chennai, Tripura, Soweto, Ibadan, Rabat, Thailand (Bangkok), Kinshasa, Ethiopa, Cameroon, Miryalaguda, Karnataka, Dar es Salaam, Mozambique, Conakry, Hyderabad, Lebanon, Abidjan, Dakar, Khartoum, Lucknow, Mumbai, Pune, Bansberia, Cairo, Lagos, Yaoundé, Benin, Pretoria, Tadepalligudem, Betul, Tripoli, Algeria, Abu Dhabi, Accra, Cape Town, Subra al-Haymah, Lubumbashi, Oman, Jaipur, Algiers, Morocco, Bulawayo, New York, Kaduna, Ahmedabad, Ballia, Giza, Bangalore, Mbuji-Mayi, Ghana, Surat. Request A Quote

Request A Quote View Certificate

View Certificate Weight Calculator

Weight Calculator Download Brochure

Download Brochure